On October, 2023, as part of the M-ERA.NET project “TRANSITION”, we had the opportunity to visit our project partners in Ljubljana, Slovenia and tour their facilities at the Slovenian National Building And Civil Engineering Institute (ZAG).

The purpose of this trip was to gain insights into how other laboratories conduct their research, review the results of tests conducted regarding the project thus far, and establish some future goals and guidelines for the project.

What did we do during our visit

Even though we had already met all of our project partners from ZAG trough online meetings, this was a great opportunity to meet everyone in person. On the first day of our visit, we had a meeting where they introduced us to their ongoing projects. Additionally, during the meeting, we set goals for the upcoming week, which primarily focused on preparations for the Open Day scheduled for Thursday. We agreed to create multiple posters showcasing ZAG’s ongoing projects, including the project “TRANSITION”, and to develop a 3D model for a printing demonstration during the Open Day.

Later on, we had another meeting during which we discussed the process of writing research papers for this project. We also shared our thoughts on the key factors to consider when selecting a journal for scientific papers, creating a catchy title among other valuable tips.

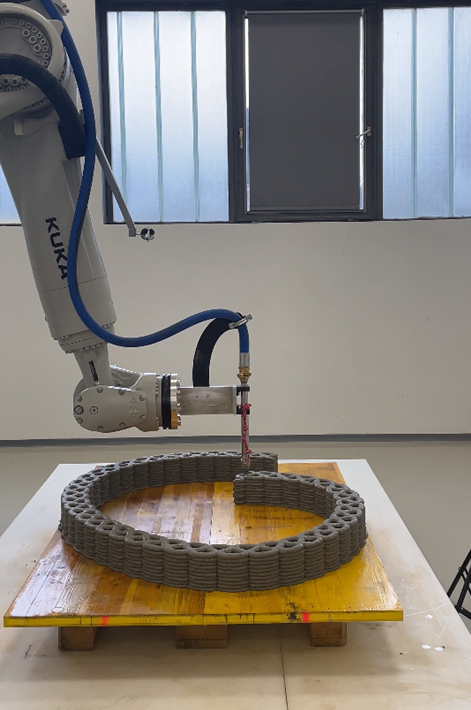

The next day we did a test run of the new model created for 3D printing for the Open Day and worked on the posters.

Figure 1. 3D printed object created for the Open Day.

The following day, we had a brief meeting, during which we discussed the different approaches on how Riga Technical University and ZAG are designing concrete mixtures. We mostly discussed the fundamental principles of volumetric mix design of concrete.

On the same day, we went on a tour to see the Structures Laboratory. The laboratory is equipped with all the necessary equipment for conducting earthquake resistance and fire resistance tests on structures, as well as large-scale element tests, anchor tests and more. Even though our tour was short, the insights shared by our guide – the head of the laboratory – left us amazed. We were especially impressed by the wide range of scales at which they can perform tests, from measuring small element elongations with remarkable precision to conducting tests in which a full-scale house can be subjected to fire. Additionally, we enjoyed their ability to relatively quickly rearrange the large-scale testing equipment to suit the dimensions of any new element or construction that has to be tested.

Figure 2. Railroad concrete bearings made for large-scale testing in Structures Laboratory.

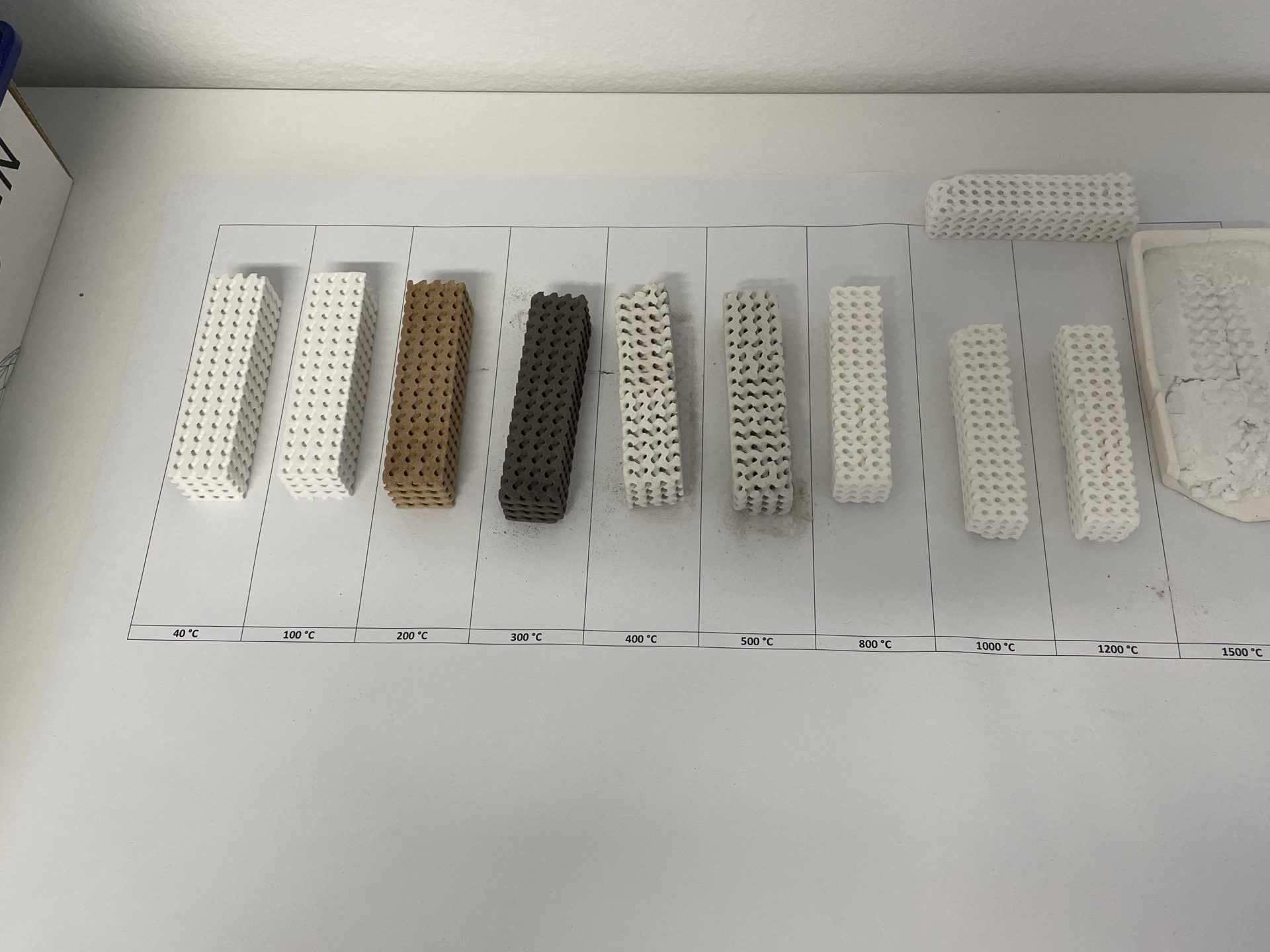

On Thursday, we took part in the Open Day, where we had a chance to visit other laboratories and view their presentations of the work they are conducting. For instance, we watched a simulation of facade damage caused by hailstones, observed some chemical reaction experiments, and more. What we found the most captivating, was ZAG’s presentation of the powder bed 3D printer. During the Open Day, we also presented the main goals, process and planned results and the TRANSITION project.

Figure 3. Powder bed 3D printed samples.

On Friday, we enjoyed another brief excursion, during which we visited the concrete testing laboratories. Particularly impressive was the enormous, automatically operated climatic room located in the basement floor of one of the buildings, where hardened concrete samples were sorted based on the day when they were scheduled for testing.

Figure 4. Automatic climate chamber, located in one of the basement rooms.

During the excursion, we also visited a laboratory where the freeze-thaw tests were conducted using both ultrasound in accordance with the Slovenian standard and mass loss according to European standard. Additionally, we saw broken concrete samples that had undergone a toughness test, referred to as the “pizza” test, in which a round shaped concrete sample is split into three parts. We also had the opportunity to observe shrinkage and creep testing devices.

Figure 5. On the left and top right – freeze-thaw test samples, on the bottom right – “Pizza” test sample has been tested for toughness.

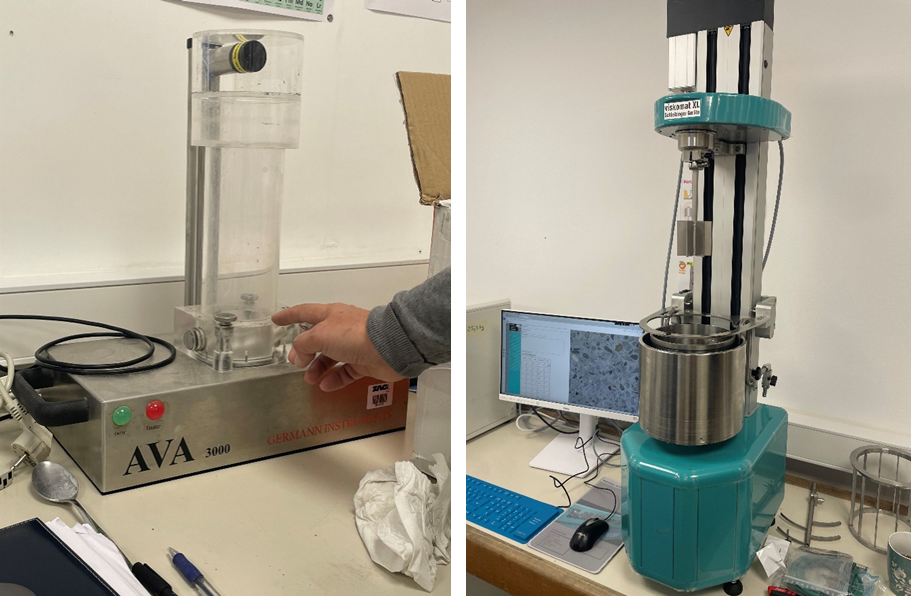

We observed some of the equipment necessary for testing concrete in fresh state as well. This included a calorimeter used to measure the speed of concrete hydration, a device for measuring the distribution of entrained air-voids in fresh concrete, both a small mortar rheometer and a recently bought larger concrete rheometer, which was being set up as we toured the laboratories.

Figure 6. On the left – a device for measuring the distribution of entrained air-voids in fresh concrete; on the right – concrete rheometer being set up.

Overall, we were lucky to receive such a warm welcome and managed to gain some valuable insights into the possibilities of concrete research. It was clear that the people working at ZAG are genuinely passionate about their work. Feeling inspired after the trip was the most important part for us. We would also like to mention that the researchers working ZAG are lucky to be located in such a mysteriously beautiful city as Ljubljana, which is particularly well-suited for a visit during the autumn season.